Set up & Applications

We operate and refine

....one of only a handful of home-built sophisticated electrospray deposition systems globally

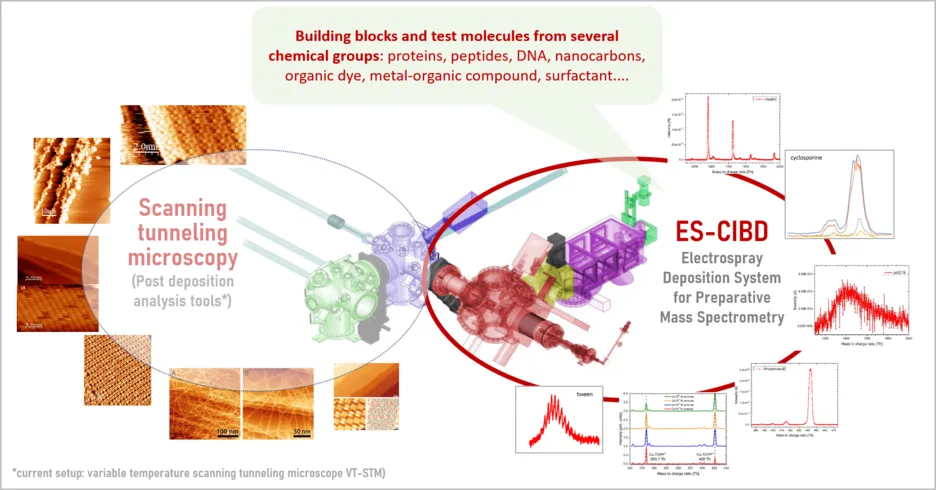

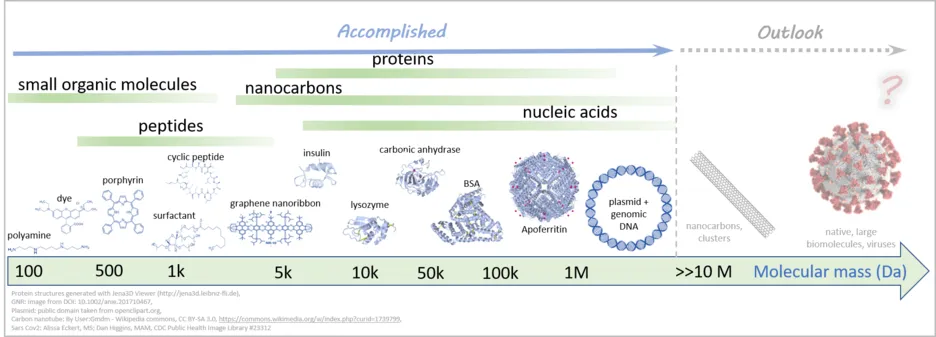

With the current set-up, various biomolecules (proteins, peptides, DNA), small organic compounds (dye, polyamines, surfactant), nanocarbons (graphene nanoribbons GNR), and metal-organic complexes (porphyrins and catecholates) were successfully processed in our lab (publications in preparation), with numerous molecules from a broad spectrum of chemical classes in the queue and access to further test objects and methods via collaborating groups.

Focus of Research and Development

Nanoscience - perspectives and challenges at a glance

Nano-Science/Technology operates with molecular structures with magnitudes down to the atomic level, when size of the objects constitutes micro- and macroscopic properties of the materials.

One focus of current global research in the field is on unlocking the vast potential of bio-organic, metal-organic, nanocarbon or other organic building blocks to design sophisticated nanoarchitectures exerting unique electronic, optical, magnetic, mechanical and chemical properties with the capability to push the development of modern nanoelectronics, organic circuits and solar cells, novel materials, (bio)sensors, of quantum computing and data storage devices.

Instrumentation for atomic-clean preparations and investigations: Specific and tailored properties of the structures built on the surfaces of solid supports are ensured by precise manipulation and control of the materials and structure-building processes realized by ultra-high vacuum (UHV) and optionally, low temperature conditions, both well-established at the department.

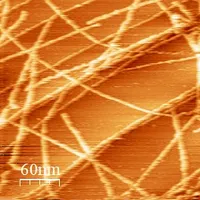

Surfaces are usually “coated” with molecules islands and mono- or multilayers by classical thermal sublimation methods (MBE, OMBE) or, in particular for delicate species, by the in-house developed “electrospray ionization - controlled ion beam deposition” (-> ES-CIBD) technology. Subsequent investigations can be conducted by scanning probe microscopy (STM, AFM) or spectroscopy (XPS).

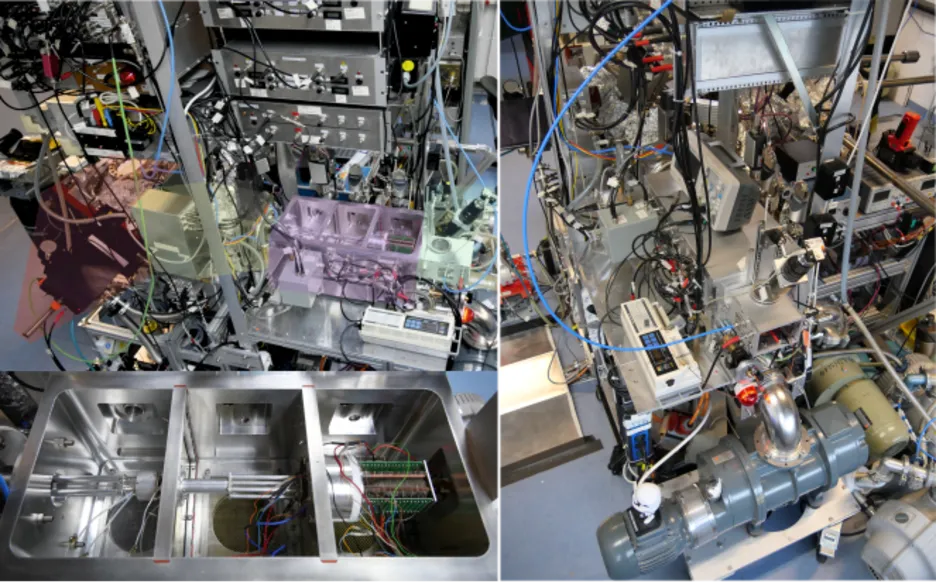

ES-CIBD Instrumentation - Overview

Deposition and surface analysis

- ESI deposition system (UHV) connected in-line to a commercial Arhus VT-STM for in situ scanning tunneling microscopy

-

Further analysis tools (JT-STM, AFM, XPS ...) will become accessible when portability of sample is ensured (portable preparation port in development, funded by FET Europe)

Deposition of fragile building blocks by preparative mass spectrometry for on-surface analysis: As one of the globally very few systems only, the ESI group provides a unique in-house developed deposition system based on electrospray ionization (ESI) and an efficient ion transmission and purification technology (-> ES-CIBD). The integrated system with an ESI source and an ion transmission and purification system comprising innovative ion guides and a novel digital mass spectrometer enables preparation of contamination-free layers of multifunctional thermo-labile or non-volatile species in a highly-controlled manner with virtually no size limit.

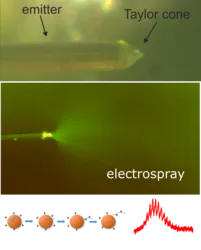

Principle of preparative mass spectrometry: Molecules dissolved in a suitable carrier are nebulized and ionized by a high voltage (HV) source (= electrospray ESI). Resulting gas phase ions are transmitted through several consecutive ion guides operated at different vacuum levels (decreasing from ambient pressure to 10-10 mbar) while being purified and mass-selected in a quadrupole mass spectrometer and finally landed on the target in UHV.

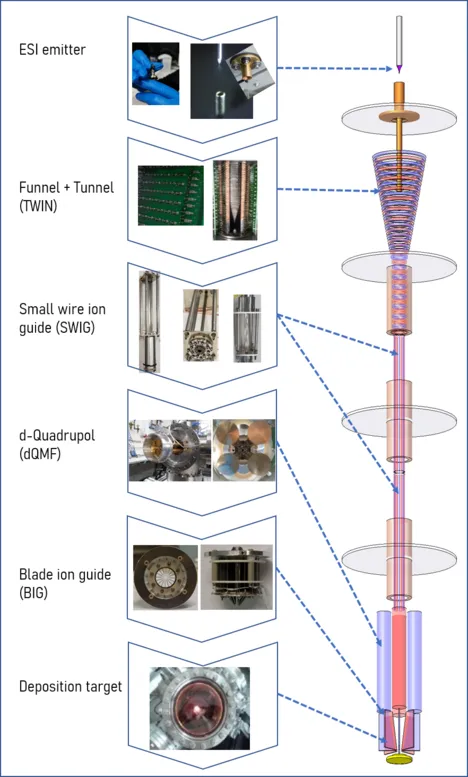

ES-CIBD Components

Development of the ES-CIBD system:

In the course of the last decade the group has developed a versatile and highly efficient deposition tool for use with fragile organic molecules not manageable with other UHV-compatible deposition methods. Key improvements concern the ion guides and the digital mass spectrometer (patents pending).

ESI source

Electrospray ionization (ESI) is a method to generate ions from a sample in a liquid by a high voltage (HV) potential applied between an emitter providing the sample in an electrolyte and the opposite transfer capillary (counter electrode) directed towards the first vacuum stage. Our home-made setup basically follows the classical ESI principle as it is realized in established analytical systems.

Ion guides

The novel ion guides are quite differently shaped according to their individual functions:

- a funnel-tunnel combination named TWIN used to guide ions from ambient to first vacuum stage upon removal of the vast majority of residual neutral gas,

- three consecutive multipoles designed by multiple wire-like electrodes eponymous for their designation as SWIG (small wire ion guide) used to clean-up the ion beam further,

- a focusing conical multipole made from metal sheet electrodes localized at the ions outlet interface, used to focus the ion beam leaving the quadrupole towards the sample (BLADE)

Digital quadrupole

Located down-stream to the last SWIG it serves as mass selector and is run in a digital mode. This allows for virtually unlimited m/z values opening the door to analyze also extremely high-mass species in the multiple MDa or even GDa range which are, to date, hardly accessible with standard equipment

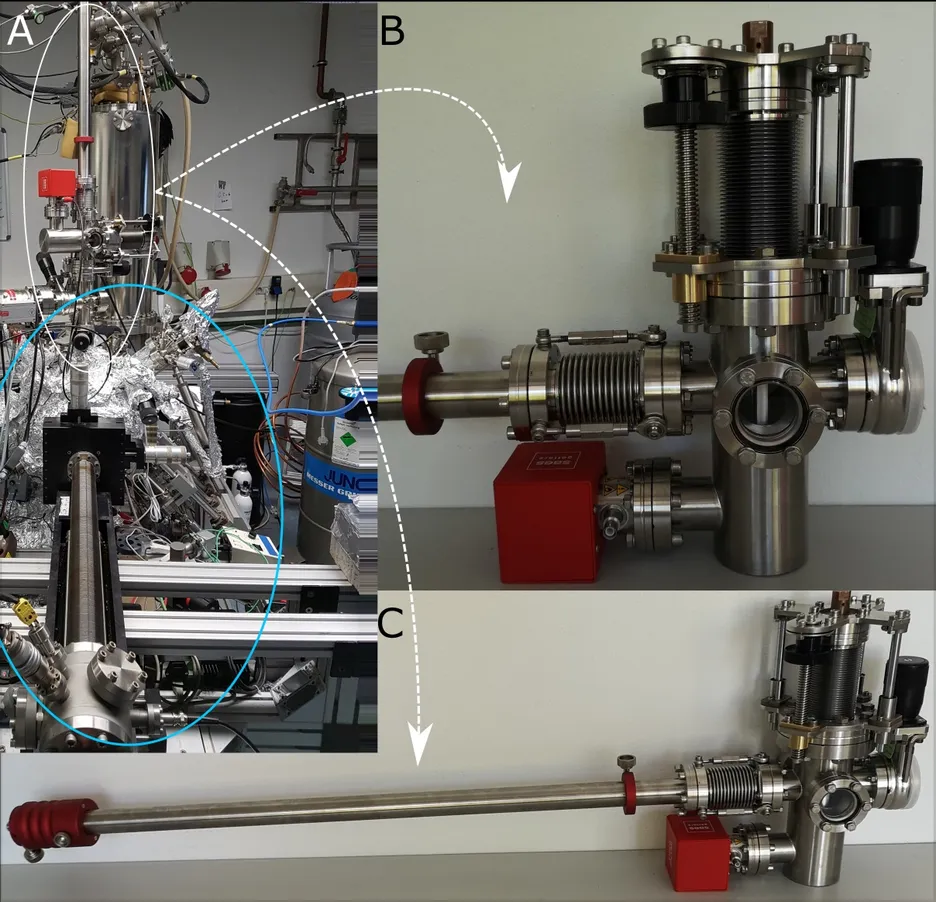

Portable Preparation Port (PPP)

The PPP device is developed within the MOLShutte project of EU. (No. 946223) and received support by e-conversion.

The PPP shall enable smooth transfer of samples crafted in the ES-CIBD device to any other analytical system useful in surface science such as LT, JT and VT – STM, AFM, XPS, and more. The device is designed to keep UHV and low temperature conditions while transferring the samples even over considerable distances to e.g. a synchrotron.

Specifications of the pilot version:

- Four transport slots for different preparations

- Liquid nitrogen cooling using adaptable dewars

- Flag-style sample holders with piggyback option

- Fast access ports to various analytical tools reaching UHV within less than 1 hour